Is Rubber Roofing Environmentally Friendly?

Earth Day falls on April 22 every year, but for many companies, a newfound commitment to sustainability and environmentally friendly practices is a year-round event. If you’re concerned about carbon neutrality, or expanding your net-zero efforts as a business, you might be surprised to discover just how impactful rubber roofing can be.

In this blog post, we’ll discuss the main types of rubber roofing, and what makes them so eco-friendly.

The Three Main Types of Rubber Roofing

There are three main types of rubber roofing, all of which are environmentally friendly:

There are three main types of rubber roofing, all of which are environmentally friendly:

- Polyvinyl Chloride (PVC): This single-ply roofing option is sustainable largely because at the end of its functional life as a roof, it can be recycled to create new PVC membranes.

- Modified Bitumen: Modified bitumen is made of compounds containing plastics or rubber, and is usually mixed with fiberglass. Though it offers some sustainability advantages, it’s the least sustainable of the three main types of rubber roofing, largely because it ends up in landfill at the end of its life.

- Ethylene Propylene Diene Monomer: Better known as “EPDM,” this single-ply roofing option is shown to have the lowest environmental impact among the three main types of rubber roofing. This is largely due to its long service life, durability, and its ability to be recycled and reused.

Why Is EPDM Roofing the Most Environmentally Roofing Option?

There are a wide array of roofing options out there…so what makes EPDM the most environmentally friendly? Let’s go over some of the top attributes.

Resilience & Durability

EPDM roofing is both durable and resilient. When cared for and maintained, it can last for several decades, perhaps even up to 40 or 50 years. And when issues do arise, it’s easy for professionals to repair.

Its Low Global Warming Potential

According to a 2010 Life-Cycle Assessment report from the GreenTeam, Inc. and TEGNOS research, EPDM rubber roofing is the most sustainable rubber roofing option. The study was one of the first in the construction industry that closely examined the entire lifecycle of the product and not just the material.

Compared to other rubber roofing options, like TPO, the study found that EPDM emitted the lowest number of kilograms of carbon dioxide per square foot.

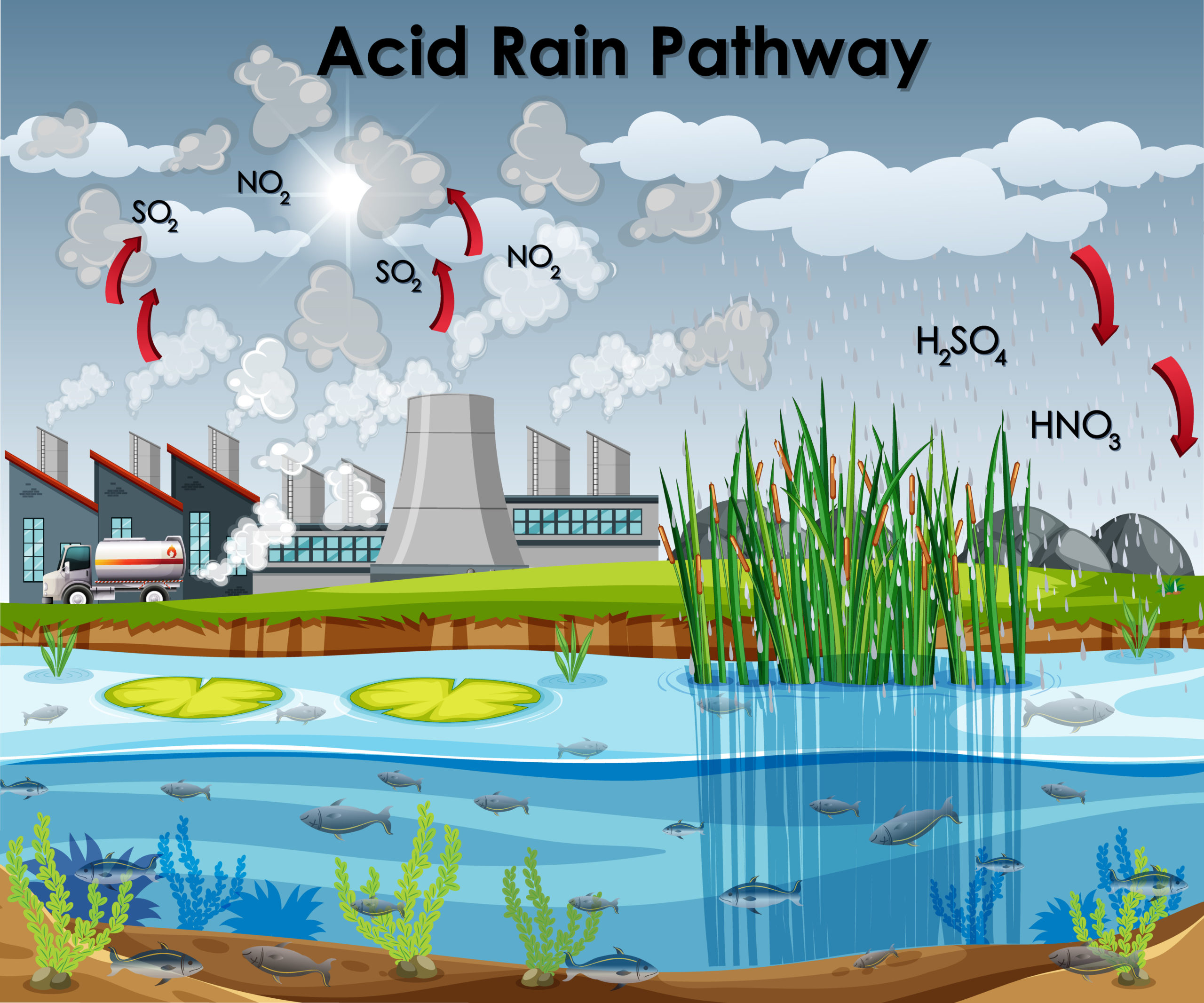

Lower Smog & Acid Rain Impact

In the same Life-Cycle Assessment report, researchers also discovered that EPDM had the lowest smog and acid rain potential.

The study looked at EPDM, TPO, PVC, and SBS, as well as attachment methods and membrane color.

Specifically, non-reinforced, fully adhered white EPDM had the least amount of nitric oxide (NOx) emissions (0.05 kilograms), as well as the lowest rate of hydrogen ions (H+) at 8.8 moles.

Lower Energy Consumption During Manufacturing

EPDM is typically made from recycled materials. This is environmentally friendly in a few ways. One, it relies on existing materials and doesn’t tap into new resources. And two, recycling to create new EPDM typically draws less energy during the manufacturing process.

Hassle-Free Solar Panel Installations

If you want to increase your sustainability efforts by installing solar panels, EPDM is a great roofing choice.

If you want to increase your sustainability efforts by installing solar panels, EPDM is a great roofing choice.

With this type of material, professional roofers can install solar panels using a ballasted mounting system, which doesn’t require any drilling/penetration. That way, you won’t have to worry about any potential damage to your roof during installation.

Get Environmentally Friendly Solutions From Summit Commercial Roofing

Are you thinking about installing a new roof on your property? Summit Commercial Roofing specializes in EPDM rubber roofing installations. If you have questions about rubber roofing or the installation process, we’re here to help. Please contact us today to request a consultation.